Mobile phone batteries are more than just power packs. They are carefully engineered systems that store and release energy through chemical reactions and precise design.

Modern phones use rechargeable lithium‑ion batteries, which convert chemical energy into electrical energy to power everything from calls to apps and cameras.

Understanding how they are made, how chemistry drives them, and how health is measured helps you appreciate the technology inside your device.

How are mobile phone batteries manufactured?

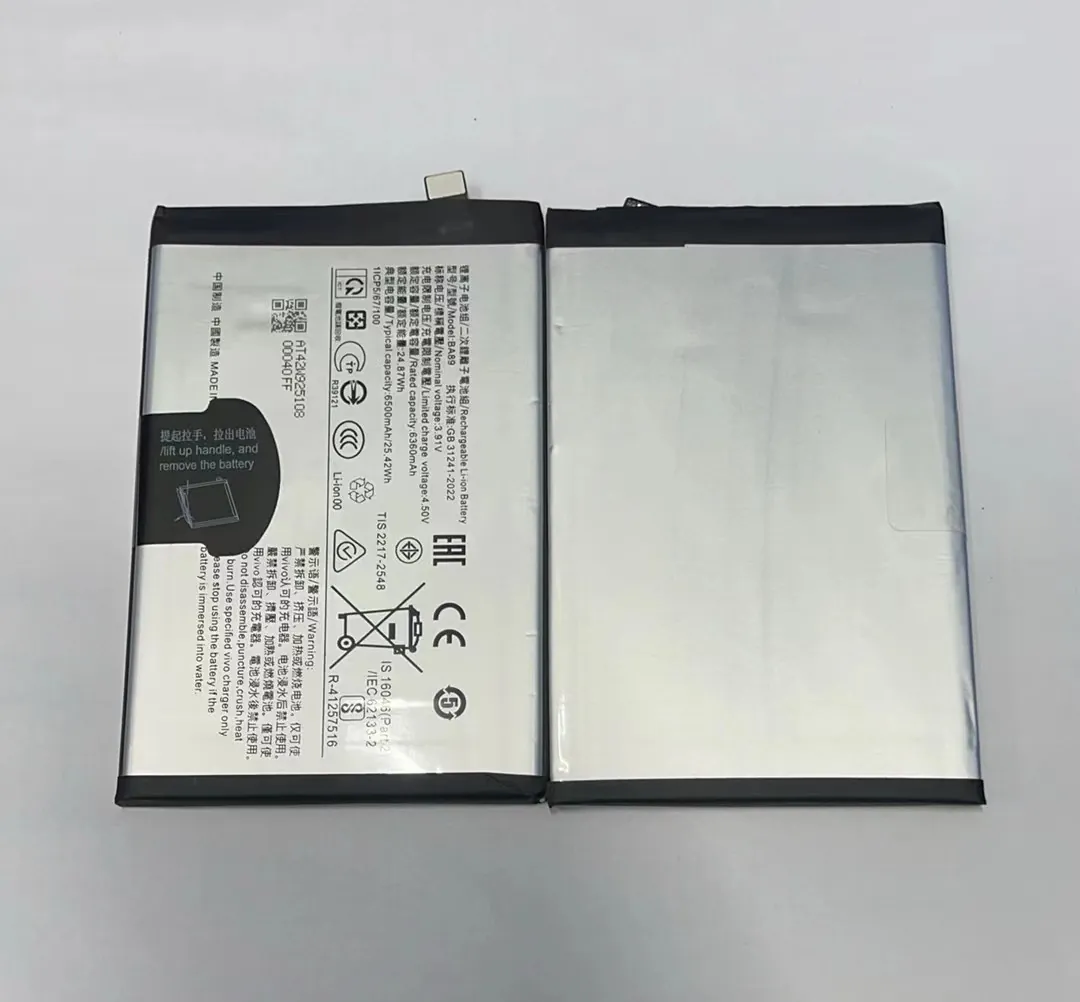

Mobile phone batteries start as a collection of raw materials and end up as sealed units ready to power your device. Most phone batteries today are lithium‑ion or lithium‑polymer types.

Manufacturing begins with preparing electrodes, assembling battery cells, and integrating safety systems before packaging into a finished battery unit.

At the heart of the battery are the anode (negative), cathode (positive), and electrolyte. The cathode often uses lithium‑based compounds while the anode is typically carbon‑based. Electrolyte liquids or gels help lithium ions move between electrodes. Inside factories:

- Electrode materials are mixed and coated on thin metal foils.

- Layers are dried and cut before being stacked or wound together.

- Cells are filled with electrolyte and sealed.

- Battery management systems and safety features are installed.

- Testing ensures each battery meets standards before shipping.

The result is a compact, high‑energy battery capable of many charge cycles. Manufacturing precision and material quality determine battery performance and reliability.

What chemical reactions power phone batteries?

At the core of a phone battery are chemical reactions between the materials inside. These reactions let the battery store and release electrical energy.

When a lithium‑ion battery charges and discharges, lithium ions move back and forth between the anode and cathode through the electrolyte.

Here’s how it works:

- Charging: Electricity from the charger drives lithium ions from the cathode into the anode. The anode stores these ions.

- Discharging: When you use the phone, lithium ions travel back to the cathode. Electrons flow through the phone’s circuit, powering it.

This movement of ions and electrons produces the electrical energy your phone needs. The efficiency of this process determines how much energy the battery can store and how long it lasts between charges.

Different materials affect the performance of these reactions. For example, newer anode materials like silicon composites can store more ions and increase capacity, while changes in cathode chemistry affect energy density and cycle life. [turn0search5]

How is battery health measured?

Phone battery health is not measured by a single number. It combines several indicators that show how well the battery can hold and deliver energy over time.

Battery health measurement looks at capacity, internal resistance, and how many charge cycles the battery has gone through.

Common battery health terms:

- State of Charge (SoC): Shows how full the battery is at a given moment.

- State of Health (SoH): Measures how much capacity the battery has lost compared to when it was new.

- Internal resistance: Higher resistance means the battery is aging and less efficient.

Manufacturers use software and sensor data to estimate these values. Direct measurements can include voltage, temperature, and resistance readings, which help determine how the battery performs under load. Some advanced methods use electrochemical impedance to assess the battery’s internal characteristics more precisely. [turn0search1][turn0search7]

As a battery ages, capacity decreases and resistance increases, which shows up as shorter battery life or quicker drains. Battery health metrics help apps and the operating system optimize charging and usage to extend lifespan.

What future battery technologies are emerging?

Battery technology continues to evolve as engineers try to improve energy density, safety, and charging speed. Tomorrow’s phone batteries may look very different from today’s.

Emerging technologies include solid‑state batteries, new anode and cathode materials, and alternatives like sodium‑ion batteries that may offer better stability or lower cost.

Some of the key trends:

- Solid‑state batteries: These replace liquid electrolytes with solid materials, potentially increasing safety and energy density.

- Silicon‑enhanced anodes: Silicon can store more lithium ions than traditional carbon, promising higher capacities.

- Sodium‑ion batteries: Sodium based systems are similar to lithium but use more abundant materials, which could reduce cost and environmental impact.

- Nanotechnology: Engineering battery materials at the nanoscale may improve ion movement, increasing performance and cycle life. [turn0search3][turn0search31][turn0search34]

These technologies are in development and may first appear in prototypes or niche markets before becoming widespread. The ultimate goal is longer‑lasting, faster‑charging, and safer batteries for mobile phones and other electronics.

Conclusion

Mobile phone batteries are complex systems built through careful manufacturing and driven by chemical reactions that move ions to produce power. Battery health depends on capacity and internal performance over time. Future technologies aim to make batteries safer, more powerful, and longer lasting as demand for portable energy continues to grow.