Smartphones often drain their battery by midday — that feels frustrating when you need them most.

The lack of clear battery type info makes it harder to compare phones.

Most smartphones today use lithium‑ion or lithium‑polymer batteries because they offer high energy and rechargeability.

If you want to choose or change phone batteries wisely you need to know what types exist and why manufacturers pick them. Let’s explore.

Which battery chemistries are found in smartphones?

Many phone makers rely on a few main battery chemistries. The two most common are lithium‑ion (Li‑ion) and lithium‑polymer (Li‑Po).

The core battery chemistry in almost all modern smartphones is lithium-based — usually Li-ion or Li‑Po, because they balance energy, size, and safety.

When picking battery chemistry, most smartphone makers choose lithium‑based types. Li‑ion packs have a liquid electrolyte, and Li‑Po uses a gel or polymer electrolyte. These chemistries store a lot of energy per gram and size. They also recharge well and keep low weight.

Why lithium chemistry is dominant

- Lithium is a light element. That helps keep phone weight low.

- Lithium cells can deliver strong energy for their size. That fits slim phone bodies.

- These batteries recharge many times — good for daily phone use.

Some older phones or simple devices used nickel‑metal‑hydride (NiMH) or nickel‑cadmium (NiCd). But those chemistries are almost gone from modern smartphones. They have lower energy density and more waste concerns.

Differences between Li‑ion and Li‑Po

| Feature | Li‑ion | Li‑Po |

|---|---|---|

| Electrolyte | Liquid | Polymer or gel |

| Shape flexibility | Rigid cylindrical or prismatic | Flexible pouch, slim shape possible |

| Weight and thickness | Slightly heavier / thicker | Lighter / thinner possible |

| Use case | Popular in older or high‑drain phones | Favored in slim, light phones |

Li‑Po allows thinner battery packs, so many newer phones go with Li‑Po to help make the phone as slim as possible. Li‑ion still appears in phones where cost or stability is priority.

Because of these traits, Li‑ion and Li‑Po dominate in phone batteries.

How are phone batteries manufactured today?

Battery manufacturing involves precise chemical mixing, layering electrodes, and strict quality checks. Mistakes can cause poor battery life or safety issues.

Modern phone batteries are built by layering anode, cathode, and electrolyte in a controlled factory process to ensure performance and safety.

Battery factories start with raw materials like lithium salts, graphite for the anode, and metal oxides for the cathode. They mix these in slurry, coat them on thin metal foils, then dry them. After drying, layers are stacked (for Li‑ion) or rolled/pouched (for Li‑Po). Then factories insert electrolyte, seal the battery, and test it for capacity, voltage, and safety.

Typical manufacturing steps

- Electrode preparation: mix active materials with binders and solvents.

- Coating: apply slurry onto thin metal foil (copper for anode, aluminum for cathode).

- Drying and pressing: remove solvent, compress to correct thickness.

- Cell assembly: stack or roll electrodes with separator.

- Electrolyte filling (Li‑ion) or drying (Li‑Po gel), then seal.

- Formation charging cycles: condition the battery, balance cells.

- Quality testing: measure capacity, internal resistance, leakage, safety under stress.

Manufacturers use clean rooms and strict humidity/temperature control. That avoids moisture, which harms battery life and safety.

Why strict process matters

- Tiny impurities or moisture can reduce lifespan or cause swelling.

- Misaligned electrode layers can reduce capacity or cause short circuits.

- Uneven electrolyte filling leads to inconsistent performance or overheating risk.

Because of this, battery makers invest heavily in process control and testing.

Industry standards and safety

Battery makers follow global safety and quality standards. They test for overcharge, over‑discharge, high temperature, and mechanical stress.

They also screen materials for purity. That reduces risk of battery failures or accidents.

After sealing, they perform formation cycles — charging and discharging the battery several times. That helps activate the internal chemistry and detect early failures.

In the end, only cells that pass all tests go out to smartphone makers. The result is stable, high‑quality battery units ready for phone assembly.

Are there differences between brands' battery types?

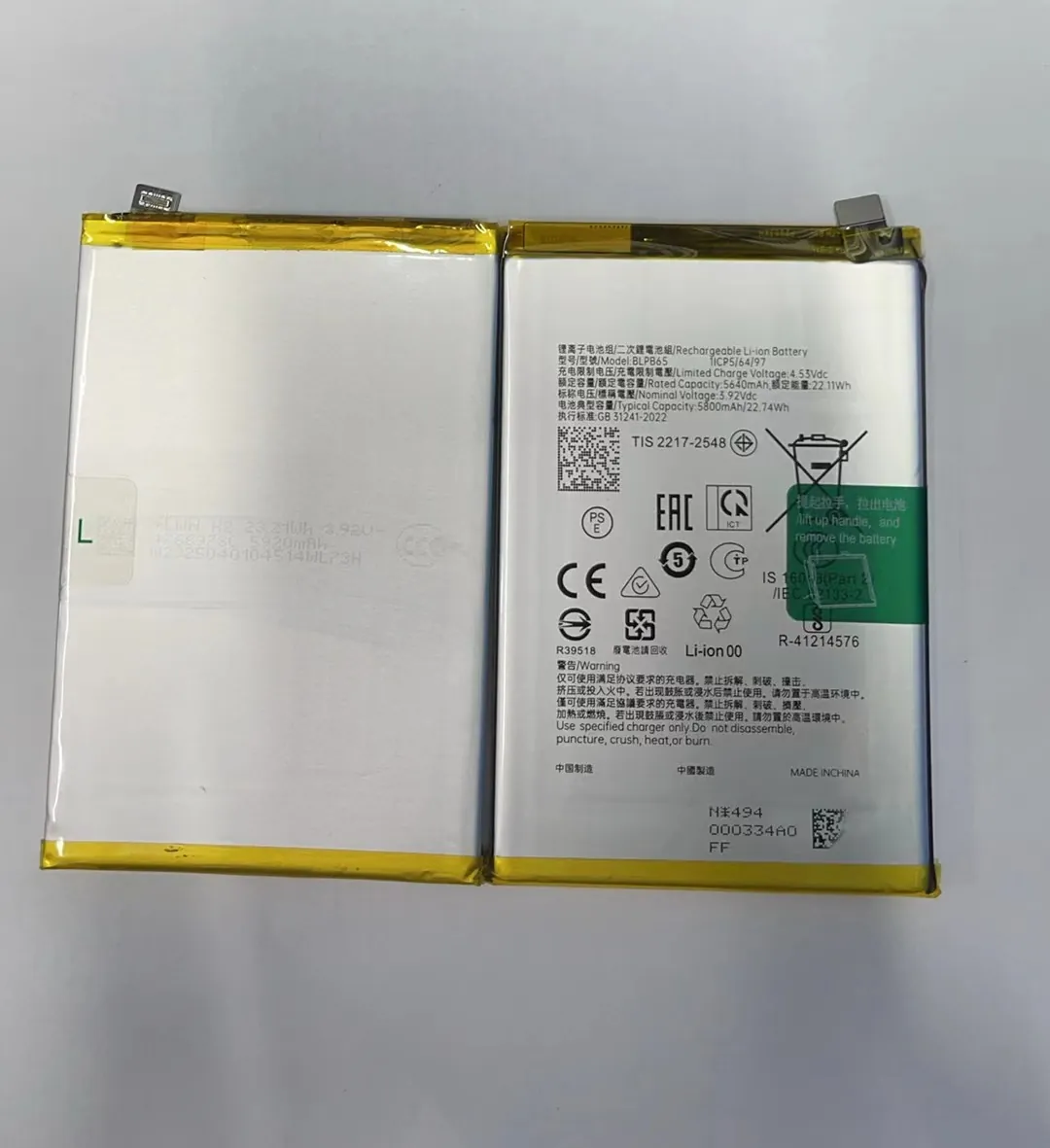

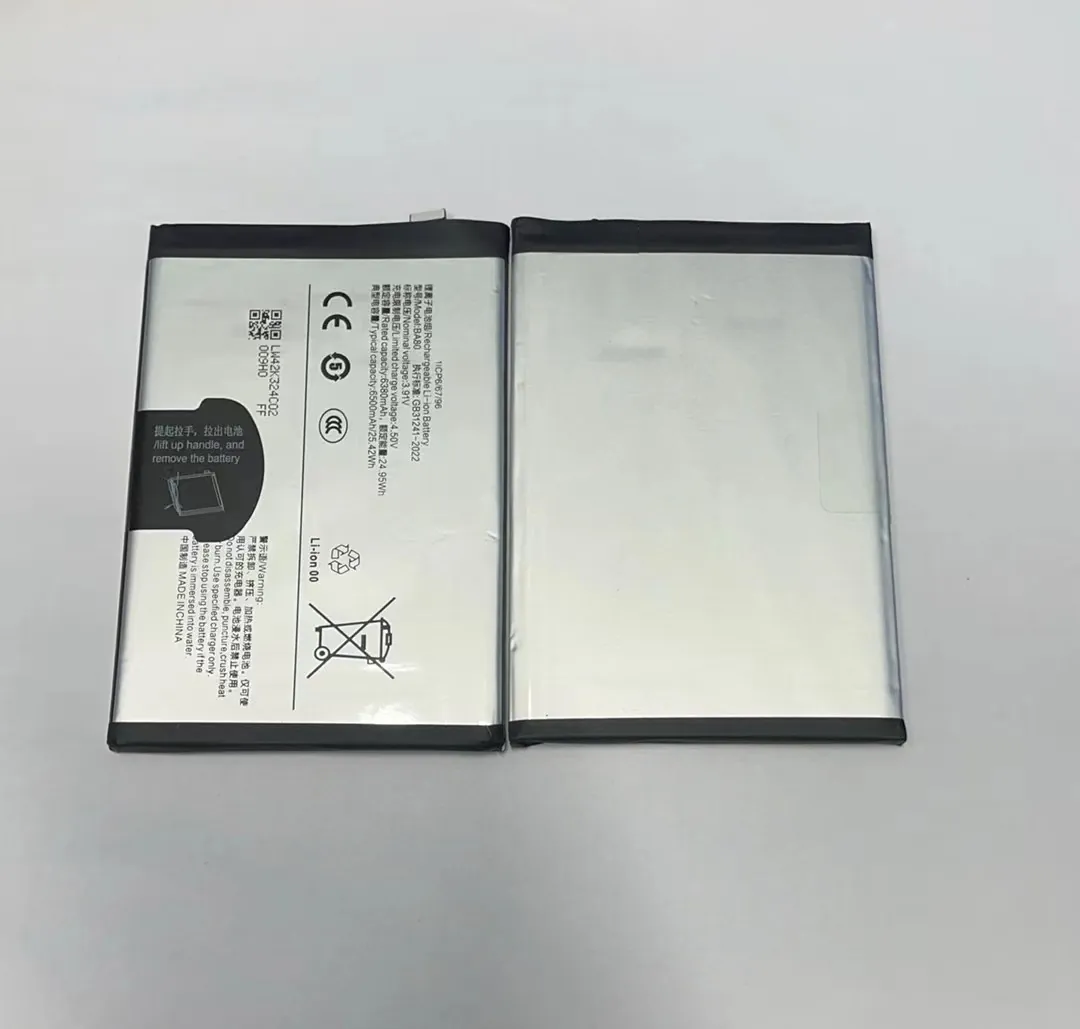

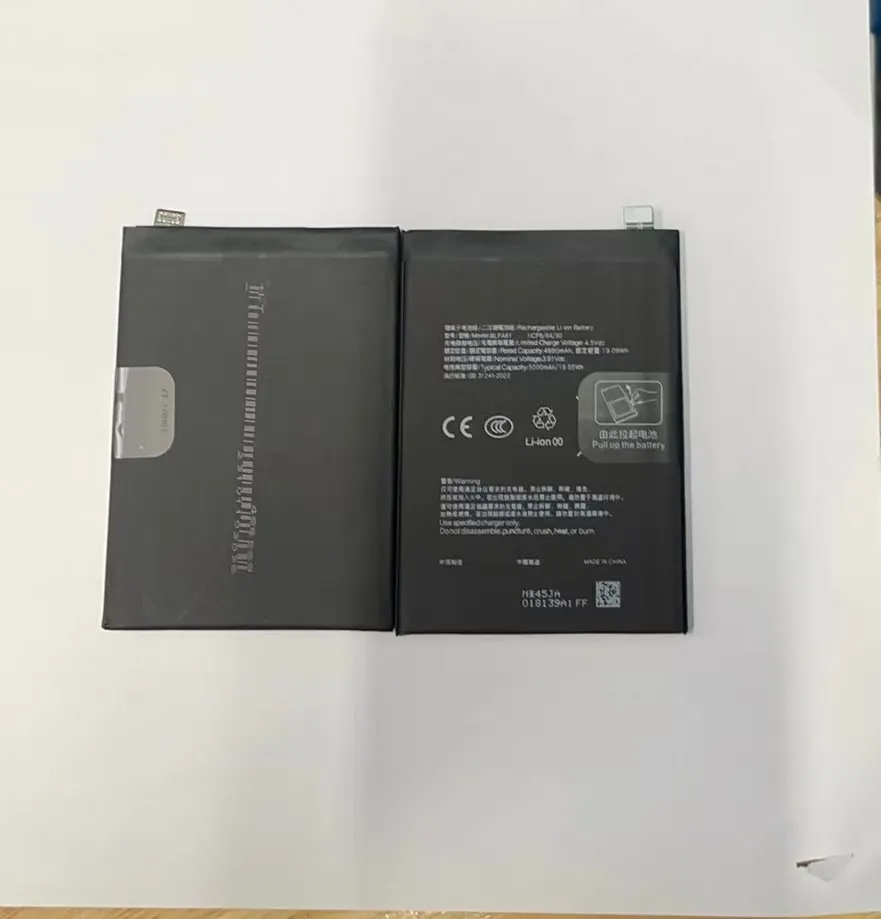

Phones from different brands often use similar battery chemistries — but capacity, shape, safety design, and manufacturing quality can vary a lot.

Most brands use Li‑ion or Li‑Po. Differences come in capacity, cell design, and battery packaging quality rather than chemistry itself.

Even with same Li‑Po battery chemistry, one brand might offer higher capacity or use safer battery protection. Others might cut costs and end up with lower quality, shorter life, or swelling.

What varies across brands

- Capacity and size: some phones use large battery packs (4000–5000 mAh) for long life, others use compact ones for slim design.

- Number of cells and shape: a battery pack may use a single pouch cell or multiple cells. Some brands stack cells differently to fit phone shape.

- Battery protection layers: good brands add protective circuits for over‑charge, over‑discharge and overheating. Cheaper ones may skimp on safety.

- Testing and quality control: top makers follow strict manufacturing standards. Others may have less rigorous QA.

- Overall performance and lifespan: a battery with 3000 mAh from Brand A may outperform a 3500 mAh battery from Brand B if Brand A uses better materials and QC.

Comparison example of two hypothetical phones

| Feature | Phone Model A (Brand A) | Phone Model B (Brand B) |

|---|---|---|

| Chemistry | Li‑Po pouch | Li‑Po pouch |

| Capacity | 4500 mAh | 4600 mAh |

| Battery protection | Full circuit + thermal sensor | Basic circuit only |

| Cell quality | High‑grade materials, tight QA | Budget materials, loose QA |

| Likely lifespan | 600–800 cycles | 400–500 cycles |

In many cases battery life and safety depend more on cell quality and battery design than on pure chemistry.

Premium brands often design their own battery pack shape and protection system. They demand cells with consistent quality. They pay for stricter tests. That leads to longer‑lasting and safer batteries.

Budget brands or lowest cost phones may buy cheapest cells that ready for bulk. Those often have less strict QC. Buyers may notice lower battery life, faster capacity loss, or more swelling risks.

So, even if two phones use “Li‑Po 4000 mAh,” the real user experience can differ a lot. Chemistry stays the same, but engineering and quality cause real differences.

Do all phones use rechargeable batteries?

Most modern phones use rechargeable batteries. However not all portable devices or older phones do — some cheap or specialty phones might use replaceable disposable cells or non‑rechargeable power sources.

Almost all smartphones today use rechargeable lithium-based batteries, but some small or basic devices may still use removable or disposable types.

Smartphones benefit from rechargeable batteries because they recharge often and last through many use cycles. Rechargeable lithium cells work best.

Situations with non‑rechargeable power

- Very old mobile phones from early 2000s sometimes used removable NiCd or NiMH cells.

- Some ultra-basic phones, low-cost feature phones, or very small devices might use removable battery packs or disposable cells.

- Specialized devices (like some medical or emergency devices) may use non‑rechargeable batteries for shelf stability. But those are rare in phones.

Modern smartphones almost always ship with sealed rechargeable packs. They are built in and not meant for user removal.

Why rechargeable is the norm

Rechargeable batteries offer many cycles. They keep capacity over many years. They meet user needs for daily use and recharging overnight.

Disposable batteries cannot meet the power demand and cost would be high if replaced often. Also they would not fit slim phone designs.

What that means for users

If phone runs out of power, you recharge — not swap a battery. That is convenient. But sealed batteries limit manual battery replacement. So phone makers rely on battery quality and lifespan design.

For a few rugged or low‑cost phones, some may offer removable battery packs. But they still use rechargeable cells.

Conclusion

Most mobile phones today rely on lithium‑ion or lithium‑polymer rechargeable batteries because they deliver the best mix of energy, size, and rechargeability. Differences between phones come not from chemistry but from battery design quality, capacity, and protection systems. Understanding these details helps pick better phones and maintain battery health.