Your phone battery dies — so you replace it. But do you ever wonder what’s actually inside that small, sealed pack?

A mobile phone battery contains lithium-based materials, metal foils, electrolytes, and protective layers, all arranged in compact, energy-efficient layers.

In this article, I’ll unpack the layers inside phone batteries, why certain metals are used, and whether all batteries are built the same way.

What Materials Make Up a Phone Battery?

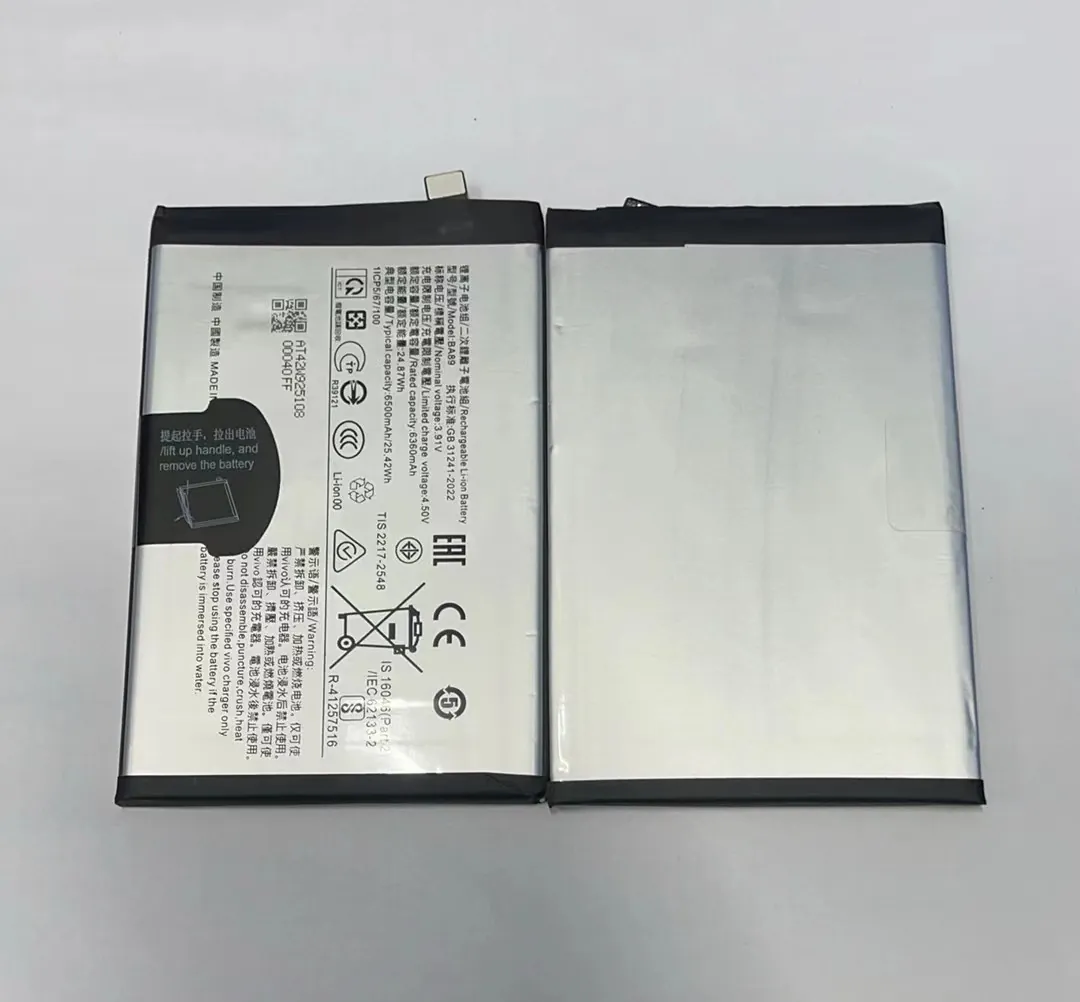

At first glance, a phone battery looks like a metal rectangle. But inside, it's a carefully layered chemical system.

Phone batteries use lithium, cobalt, graphite, aluminum, and polymer or liquid electrolytes to store and deliver energy safely and efficiently.

Core Ingredients of a Lithium-Based Battery

Here’s a breakdown of the main materials inside most lithium-ion or lithium-polymer phone batteries:

| Component | Material Used | Purpose |

|---|---|---|

| Cathode | Lithium cobalt oxide (LiCoO₂) | Stores lithium ions during charge |

| Anode | Graphite | Releases lithium ions during use |

| Electrolyte | Lithium salt in organic solvent | Transfers lithium ions |

| Separator | Microporous plastic film | Prevents short circuits |

| Current Collectors | Copper (anode) & aluminum (cathode) | Transfers electrons to/from circuit |

All these are sealed in an aluminum or polymer casing. Some batteries also include temperature sensors and circuitry for safety.

Why These Materials?

Each material is chosen for a specific reason:

- Graphite is stable and stores energy well.

- Lithium compounds offer high energy density.

- Cobalt helps improve charge cycles and battery life.

- Copper and aluminum conduct electricity efficiently.

This mix allows for small, powerful, and rechargeable batteries — just what phones need.

How Are Battery Components Arranged Internally?

All those materials can’t just be mixed. They're arranged in very specific ways to ensure the battery works — and doesn’t explode.

Inside a phone battery, materials are layered in sheets — anode, separator, cathode — and rolled or stacked before being enclosed and sealed.

Layer-by-Layer: How a Battery Is Built

Most phone batteries follow this layout:

- Cathode layer – usually aluminum foil coated with lithium cobalt oxide

- Separator – thin film that stops short circuits but allows ion flow

- Anode layer – copper foil with a graphite coating

- Electrolyte – fills the spaces between layers, enabling ion movement

These layers are either:

- Rolled into a jelly-roll cylinder (common in cylindrical cells), or

- Stacked like pancakes in pouch cells (common in phones)

Final Assembly

Once layered, the battery is:

- Enclosed in foil or hard casing

- Welded to connectors

- Fitted with a protective circuit board

- Sealed with adhesives and insulation

This structure ensures safety, efficiency, and durability in daily use.

Why Is Cobalt Used in Mobile Batteries?

Cobalt isn’t cheap — and it comes with ethical questions. So why is it still widely used?

Cobalt is used in phone batteries because it increases energy density, extends lifespan, and improves safety, especially in lithium-ion chemistries.

What Does Cobalt Do in a Battery?

In lithium cobalt oxide (LiCoO₂) cathodes, cobalt:

- Stabilizes the chemical structure

- Prevents overheating

- Improves recharge cycles

- Allows more energy storage in less space

Without cobalt, batteries might swell, degrade faster, or catch fire under stress.

Downsides of Cobalt

Despite its benefits, cobalt poses some major concerns:

| Issue | Impact |

|---|---|

| Ethical sourcing | Mined in conflict regions (e.g. Congo) |

| High cost | Raises battery and phone prices |

| Environmental effects | Mining harms local ecosystems |

Are There Alternatives?

Yes — researchers are developing:

- NMC batteries (Nickel Manganese Cobalt with reduced cobalt)

- LFP batteries (Lithium Iron Phosphate, cobalt-free)

- Solid-state options that need no cobalt at all

But for now, cobalt remains key in high-performance phone batteries due to its unmatched stability.

Are All Phone Batteries Built the Same Way?

All batteries may look the same on the outside — but internally, they vary in chemistry, design, and quality.

Phone batteries differ in materials, layer arrangement, safety features, and capacity depending on brand, price, and intended use.

Key Differences Between Phone Batteries

Here’s how two phone batteries might differ:

| Feature | Budget Phone Battery | Premium Phone Battery |

|---|---|---|

| Battery Chemistry | Basic lithium-ion | Advanced Li-ion or Li-polymer |

| Layer Structure | Simpler stacking | More efficient layering |

| Energy Density | Lower | Higher |

| Safety Circuits | Minimal | Multiple layers of protection |

| Longevity | 300–400 cycles | 800–1000+ cycles |

Custom Designs for Different Brands

Apple, Samsung, and other major brands often:

- Customize battery shape to fit device internals

- Optimize software for battery health

- Use smart charging algorithms to reduce wear

Meanwhile, cheaper batteries (especially third-party or counterfeit ones) may skip safety steps or use recycled materials, which can lead to swelling, overheating, or even fires.

I’ve seen cases where non-original batteries caused phone shutdowns or erratic behavior — that’s why high-quality, tested batteries matter, especially in professional repair.

Conclusion

Inside every phone battery is a mix of lithium, graphite, cobalt, separators, and electrolytes — arranged in precision layers. While most use lithium-ion chemistry, the exact design and materials vary by model. As battery tech evolves, we may see safer, cobalt-free options in the near future.